Not all virtual inspections will give you the same results, so before you go and add virtual inspections to your inspection toolbox, there are some things you need to consider so you get the maximum value.

So, what’s the big plan? Why are you thinking about virtual inspections? Cut costs, be more efficient, enhance safety, try out Artificial Intelligence (AI)? Or all of the above…

A mix of inspection methods such as ground, climbing, bucket truck, routine aerial, and detailed aerial patrols supplemented with advancements in viewing and data collection technologies (e.g., stabilized binoculars, digital cameras, field computers, etc) have been utilized for decades to assess system conditions and identify maintenance items needing mitigation. Maintenance and inspection teams have developed best practices to improve what they get out of these inspection methods, while there are still improvements that can be made, most utilities are quite comfortable with the planning, scope and outcomes of these methods.

Now with virtual inspections, while the objectives are the same, perform a visual inspection of the grid, identify defects, and categorize their priority level so maintenance teams can deploy crews to repair any high priority defects and schedule lower priority maintenance. The methodology, enabling technologies and subject matter experts can have a huge impact on the results from your virtual inspection program.

Getting your planning right!

If you don’t scope and plan your virtual inspections correctly you could end up spending more on these types of inspections with less return, and the CFO really doesn’t like that.

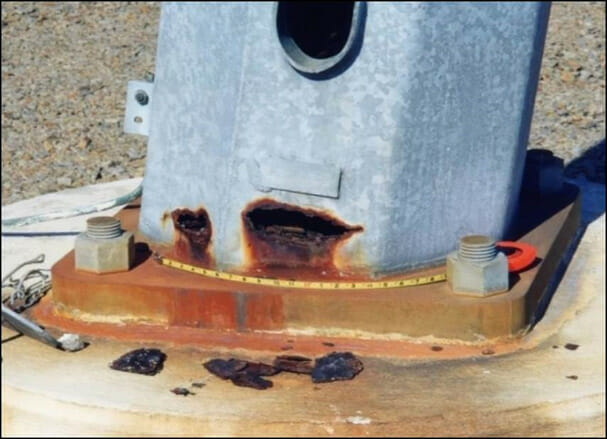

You need to determine what defects your virtual inspection will focus on, as an aerial photo will show you the grid from a different perspective relative to say ground patrol and there will be certain defects that may be more difficult to detect, for example defects at the base of a pole or structure for which the evidence is relatively small. Further, it may not be possible to effectively measure the extent of such a defect from a photo.

Image taken by foot patrol of corrosion at the bottom of the structure. Difficult to get depth and measurement of defect from a virtual inspection. Image courtesy of EDM International.

Let’s look at data capture.

Think about the number of circuits you are planning to inspect with this method, and the technology you will use to capture the data from the field. Determine if you will be utilizing drones, or manned aircraft and once you determined the method, what will be the flight strategy and profile as this impacts your cost, time and the defects you can detect. For example, if you are utilizing drones (and of course you are because drones are super cool!), you can conduct linear or orbital flight pattern or a combination of both, you can also invest in drone flight optimization software to help optimize your data capture.

And yes, drones are cool and all but have you ever tried flying one? It is not that easy, and it is not always allowed, so you also need to consider regulations and potential flight restrictions in certain areas. Regulations vary from region to region and gaining approvals for certain types of flight can be a long process (government entities are not really known for being quick) especially when seeking to perform Beyond Visual Line of Sight (BVLOS) operations. With data capture the key is to strike a balance between ensuring you get the data you need without needing to re-fly and making sure the approach is scalable.

Or were you planning a totally different approach and want to use images taken by other methods like LiDAR flights – then there are a lot of different questions you should be asking, like will it even work? Technology is rapidly changing and the ability to bolt on capturing LiDAR with what you are already doing will greatly expand the use case for the data and dramatically improve your return on investment.

Then there is the image capture technology.

Just like our mobile devices, image capture technology is rapidly advancing. Who thought 15 years ago we would utilize our phones for almost everything and they would replace our wallets and cameras. This begs the question, how do you pick the right technology and ensure that the data you have captured is usable not only for an inspection, but beyond?

Once you capture the data, what are your plans with the number of images and data that you are going to collect, where will you store it all? You have to budget for it and plan for how you will be able to access the data, make it usable so that it is not just left in a data lake (gathering dust and eventually turning into an unstructured data swamp with warning signs) until the next inspection.

We’re conducting an ongoing large-scale virtual inspection program and over just the first three-years we’ve collected so many images that if we were using printed images (we’re not 😉), and we stacked them on top of each other they would equate to the height of the Empire State Building (that is 380 meters without the spire and antenna)! So, storage, albeit electronic/digital, is definitely something to think about.

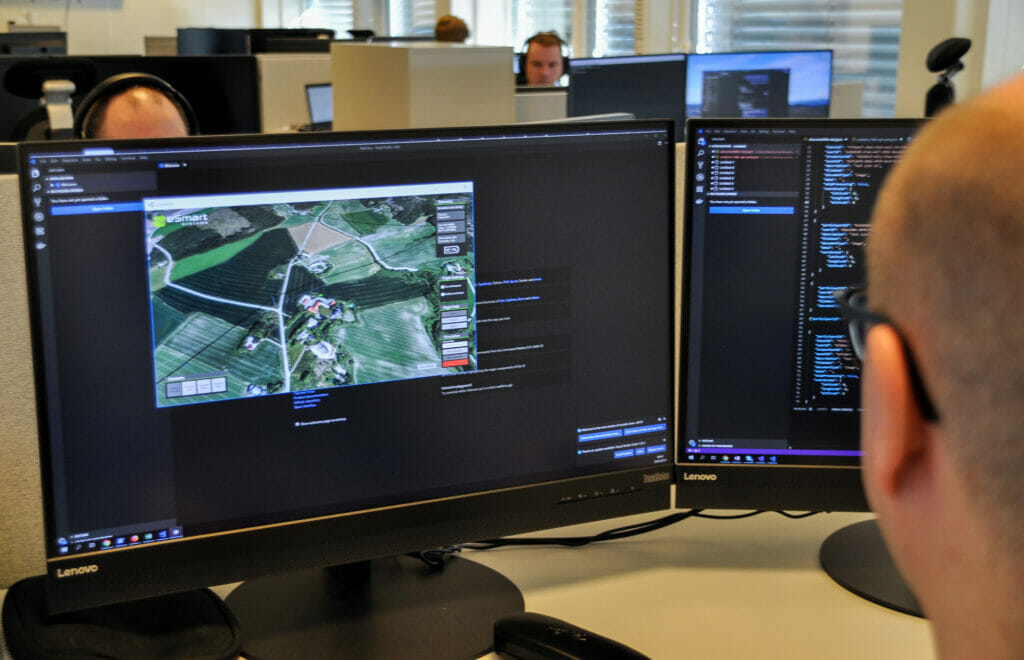

The technology to enable virtual inspections and processing of the inspection data is something that needs to be given a lot of thought. There are a lot of solutions on the market at the moment, how do you pick the right one for you? Do you know what you need? Do you know what questions you should be asking to get beyond the smoke and mirrors of an impressive demo? A couple of important points to consider…

- Can the software structure your images based on asset models?

- Can it also link the images to the metadata, and the right physical asset on the grid?

- Does the software you are considering enable efficient inspection and recording of findings?

- Does this software facilitate fast loading times for memory intensive images and quick access for inspectors? Time is money, everyone knows that.. right?

Then there is advanced technology like AI.

The new shiny tool in the toolbox, that is being marketed as the solution to all your problems. How do you build your strategy around that? One of the most important points to consider is that AI, no matter what industry you are in, needs training data (and a lot of it!). Therefore, when you are seeking an AI solution or trying to build your own, know that there are a lot of utilities who tried before you, and are now stuck with their AI in the innovation stage; because their AI will not do what they expected, it won’t solve all their problems because they simply do not have enough data to train the AI to detect the defects and components. The CFO is now cutting their budget since they are not showing any results, and they’ve had so many developers working on it that the costs have skyrocketed.

So instead of being put in that awkward position, know that AI solutions are complex and take time to develop, and they are surrounded by expectations and misconceptions. Our personal favorite is that AI will replace the Subject Matter Experts (it won’t, we promise) so managing the expectations are key. Any transition takes a little time, and Rome was not built in a day – remember?

The Subject Matter Experts.

Let’s pretend we have all that. Once you have plans for the scope, capture process and technology, the next question is – who will perform the virtual inspection? Your Subject Matter Experts (SMEs) will have the biggest impact on the value you get back. And thus it is critical to consider their experience and expertise and ensure they are trained on the technology…which needs to be easy to use and efficient, or your SMEs will quickly become disenchanted.

Planning does not end with the inspection.

If you do not incorporate consideration of the additional business processes associated with inspection work into your planning, then your return will be short lived and the value limited. We have seen utilities do this right and when they do, we find maintenance teams consistently utilizing the inspection data in their everyday work; being able to do a lot more without a field visit. Accurate inspection data can empower utilities to prioritize capital projects and save a ton of money by only focusing on assets that need to be prioritized.

There have also been instances where maintenance teams have been able to reduce the risks of unplanned outages by identifying at-risk assets utilizing accurate virtual inspection data and enhance safety, reduce costs and help ensure compliance with their own standards as well as those of the regulators.

So, before you embark on a virtual inspection initiative, stop and plan. It really can make the difference between an innovation project that gets mothballed, and one that drives efficiency gains, cost savings and automation of your business . We know you are under pressure to reduce your operation and maintenance costs, but remember not all virtual inspections are the same, nor are they the silver bullet for all of your inspection needs. However, they can represent a cost-effective solution to add to your existing toolbox and when done right can reduce your costs, drive efficiency, support your digitalization journey and, most importantly, facilitate safety and reliability improvements.

Contact us today and see how Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

Share article

Latest News & Resources

-

Watch our webinar – Disrupting the status quo: AI in utility operations

Watch this webinar to understand why everyone is talking about -

Fingrid advances grid maintenance with conditional analysis using Grid Vision®

May 2025 – Fingrid, Finland’s transmission system operator, has launched -

Could the Iberian Peninsula blackout have been avoided? What it tells us about grid reliability

When large parts of the Iberian Peninsula were plunged into -

Accurate image-based asset data: The key for successfully managing a growing grid and demand

With global electricity demand projected to grow by 4% in