We pioneered virtual inspections of energy utility assets over 10 years ago, and in that time, we have been asked a lot of questions. Here are some of the frequently asked questions that utilities seek answers to:

- We have high reliability on our grid, so why would I change my inspection method?

- We have been inspecting our assets with a proven method for a long time, why change it?

- I have heard that the AI is not ready yet, so why start implementing it now?

- Why do it now? We tried this a few years ago and it was more expensive than our traditional methods.

All valid questions, therefore we have put together ten reasons why a utility should add virtual inspections to their inspection program.

- Improve the safety of your inspections by having fewer people out in the field conducting inspections through foot patrol, climbing towers or inspecting by helicopter. Our approach is that we are hardware agnostic, so you can capture your assets out in the field via various methods and then conduct the actual inspection from your desk.

- Get a holistic and consistent view of your inspection results and remove subjectivity. One of our customers was outsourcing their asset inspections and getting inaccurate and inconsistent defect results. The customer also climbed towers that did not require climbing resulting in unnecessary costs and safety risks. With our built-in inspection workflow and multiuser experience, they now have a solution that yields results without incurring unnecessary expenses and risks.

- Identify more defects than traditional inspection methods. One of our customers identified 60% more defects with our virtual inspection program than when using foot patrols. Read our whitepaper which compares the effectiveness of foot patrols and virtual inspections here.

- Reduced inspection time. Inspecting the grid at a desk using our solution – Grid Vision®, allows the inspectors to quickly identify and confirm defect suggestions. One of our customers reduced inspection time per pole by 2/3 by deploying our virtual inspection approach and software.

- Reallocation of expensive resources. We all know that there is a skills shortage in the utility industry. With virtual inspections, you do not need to send experienced engineers into the field. You can capture the images and conduct a virtual inspection at your desk. The experienced engineer acting as a subject matter expert only needs to do the quality review using our software. This way your experienced engineers can focus on high-priority and high-value work.

- Improve your capital planning. Base your capital planning on accurate data and appropriate risk tolerances. We have supported two of our customers to move over $10 Million of inspection costs from O&M to capital by creating digital assets of their system.

- Use the data you are collecting. If you are sending out teams for inspections and collecting data let us ensure you only capture what is necessary and then maximize the usage. With over a decade of experience, we have a proven methodology for data collection to ensure that the captured data is not only suitable for a virtual inspection but for broader use beyond the inspection itself. If you are already spending your budget on collecting data then get it right the first time.

- An image tells a 1000 words. With our structured approach, we work with utility customers to collect the right number of images at the correct angle so they can be successfully utilized for a virtual inspection, as well as use cases beyond the inspection. In our approach, we link the images to the right asset, metadata, asset data, inspection data and grid topology and build your image-based digital asset that you can utilize across your organization.

- Reduce your environmental and O&M costs by conducting virtual inspections and eliminate verification visits by providing teams access to the image-based digital asset so they can conduct most of the work from their desk and only go out in the field when necessary. Working with one of our customers we estimated they could potentially save 150.000 tons of CO2 per year by adopting our approach across their grid.

- Reduce costs and drive efficiency across your organization by utilizing your image-based digital asset. Our customers are now using Grid Vision to identify common vulnerabilities, verify site access, optimize workforce management, capital planning and support regulatory reporting.

We have given 10 reasons to add virtual inspections to your asset inspection program and we have not even mentioned the value of AI.

Virtual inspections are another inspection method in your toolbox and complement your existing methods. With our approach you don’t replace your current inspection program but add virtual inspections, as certain inspections still require ground patrols like testing pole foundations and drilling for rot, etc. One of our customers has now incorporated virtual inspections as 50% of their inspection program.

So what are you waiting for? Contact us today for a free workshop where we can help you see how virtual inspections can support your operations.

In hindsight of the BNEF – The New Energy Outlook: Grids report, it is apparent that large investments across the grid infrastructure are needed to continue on the net-zero trajectory. According to the report, the power grid will double in size by 2050.

We are arriving at the fifth industrial revolution (impressively, the power grid’s implementation spans back to the second!), and it is defined by data. When being described, this is the time of technological advancements, automation, increased operational efficiency and technical assistance. And it is just in time, as these are required for us to be able to build out, maintain and connect a doubled-sized power grid in less than 30 years. So even if we call it a revolution, this is a gradual change – and lets be honest, we did see it coming.

- BVLOS flying inspected over

in a single day

The new age of powerline inspections.

When working with utilities on their infrastructure inspections, we are constantly being reminded of the immense challenges that modernization, digitalization and huge expansion poses for utilities. And we are not claiming that we can solve all of these challenges on our own, but virtual inspections can support the energy transition and is aligned with the expectations of the new revolution when it is done right.

In a recent study with Xcel Energy, virtual inspections found 60% more defects than foot patrol, a staggering result that underlines the value of complementing traditional inspection methods with new technologies and methodologies. For the virtual inspection in this study, the footage was captured primarily using state-of-the-art Phoenix Air Unmanned (PAU) drones (some by helicopter), deployed with advanced camera technology from Phase One to provide high-resolution imagery for Artificial Intelligence (AI)-assisted defect detection. The virtual inspection was conducted by EDM International utilizing eSmart Systems Grid Vision® solution.

Drones, or UAV’s (unmanned aerial vehicle, but for ease– let’s just call them drones) are the latest addition to the air space. These smaller, unmanned air crafts carry huge potential, especially when it comes to infrastructure inspections.

- With their size, drones can easily fly closer to the assets without putting a human in harms way.

- Drones are also way more sustainable than helicopters, both in carbon footprint and cost of flying.

- The imagery captured by these types of drones are ideal to use in AI-assisted virtual inspections, as they can fly closer and capture high resolution imagery.

- The accuracy of the AI will also improve significantly when the images are of high quality, and therefore save time and money for the utility.

Today’s regulatory landscape.

Another critical difference that sets drones apart from their bigger, carbon-hungry cousins is the ability to fly beyond visual line of sight, or BVLOS for short. Flying BVLOS often requires applying for a waiver from the governmental entity of aviation with clear scope and operational descriptions.

The operator must present a clear safety case on how they will deconflict with both traffic in the skies and people on the ground. These safety mitigations may include:

- limiting the operating environment,

- use of electronic surveillance equipment to monitor the airspace,

- or keeping the drone close to the infrastructure that is being inspected.

All safety mitigations are outlined in a concept of operations (ConOps) – which is provided to the aviation authority along with operations manuals and safety management systems detailing the quality of the operator.

Tying this back to the fourth industrial revolution, proponents of using drones list the increased pressure on governments to change their current approach to fit the new possibilities that technology brings. The BVLOS flying of drones to capture infrastructure data is a perfect example of a shifting paradigm.

Utilities provide the ideal proving ground for advancing BVLOS drone operations under aviation regulations. The transmission line environment is defined as

“to include use of proximity to infrastructure as a mitigation to deconflict with manned aircraft traffic”

and routine inspections fall under public interest. As drone inspections scale to larger equipment, federal regulators require the operator to convey how the specific flight operation is in the interest of the public. With the ongoing electrification, and the ever-growing need for an uninterrupted delivery of power, the interest and acceptance has increased.

Following years of lessons learned and 13,000 inspection miles later, Phoenix Air Unmanned (PAU) recently secured a nationwide waiver for BVLOS drone inspection flights. The transmission line inspection waiver unlocks BVLOS operations for all utilities recognized by the US Department of Energy, providing huge value to increase the cost-efficiency of infrastructure inspections.

in the cost of drone data acquisition

It all started with five miles.

In 2015, Xcel Energy sanctioned a five-mile proof of concept transmission line inspection using drones. Limited by site access, weather, and shortened flight distances, they kept the unmanned aircraft within visual line of sight, the field crew took two and a half days to inspect five miles. Traditional foot patrol methods would have completed the inspection in a single day, underlining that something needed to change to increase the efficiency.

Today, under the BVLOS inspection authorization, the same five-mile stretch piloted by Xcel Energy in 2015 can be inspected in one single flight. For PAU, the distance per flight has grown to ten miles with field crews averaging 45 miles of inspections per day. In July 2020, a flight team inspected over 120 miles in western Minnesota in a single day. The area provided ideal conditions for launch and recovery access, aircraft command and control link, and met all the criteria presented in the safety case to fly extended flight lengths.

Changing the regulatory landscape.

As BVLOS operations have scaled, the cost per mile for acquisition has plummeted. Initial authorizations from regulators required visual observers in a “daisy-chain” configuration to keep watch of the skies when the unmanned aircraft was out of view of the pilot. Additional personnel along the route of flight provided little economic value for drone inspections. Today, the PAU BVLOS waiver authorizes the use of a single “Electronic Observer” monitoring airspace for the pilot. Removal of visual observers and the extension of flight lengths by no longer accounting for visual observer viewing locations has led to a 46% reduction in the cost of drone data acquisition.

In 2016, 14 CFR Part 107 was introduced by the Federal Aviation Administration for commercial operations of unmanned aircraft. The rule limited operators to less than 55 pounds total gross weight. The future of drone inspections is pairing BVLOS inspections flights with aircraft that exceed the 55-pound weight limit. An increase in weight will mean an increase in capability to include flying farther with multiple inspection sensors, driving the efficiency and financial gains even further than before and provides utilities the ability to gather high-resolution RGB imagery as well as LiDAR and infrared at the same time.

Some companies – including PAU – are operating larger aircraft outside of the bounds of Part 107. In 2023, the SwissDrones SDO 50 was put into service for powerline inspections. The aircraft flies for two hours at a maximum takeoff weight of 192 pounds – carrying a suite of sensors such as high-resolution inspection cameras, LiDAR, and infrared and near-infrared cameras. Regulators recognize the need for larger aircraft operating in the National Airspace System and are working towards a new set of rules to accommodate these systems. While larger aircraft can be operated under exemptions today, rules are still years away from going into effect, but every journey starts with one step (or five miles of transmission line).

Scalable BVLOS powerline inspections via drone are available now. The foundation is being set by industry leaders who bring aviation experience when seeking approval from regulatory authorities. Operational history and use cases provided by the utility industry – paired with the transmission line operating environment – are under review by regulators. BVLOS rule making will eventually go into effect and the utility industry will be the first to benefit on a wide scale – long before commercial package delivery by drone is common (but we are looking forward to that too!).

Concluding thoughts.

The increased efficiency and financial gains from being able to acquire multiple data sources from one single flight provides a huge step towards grid digitalization and modernization. For virtual inspections to make the high returns that utilities are expecting, they need to consider the holistic inspection process and beyond, not all technologies and methodologies will deliver the same results. eSmart Systems understands the importance of creating great partnerships for our customers, to ensure our AI-assisted software can help utilities detect and identify the smallest defects on their assets, safely behind their desks and that the data captured can be utilized beyond the inspection. We believe in end-to-end solutions for infrastructure inspections, and we are happy to partner with Phoenix Air Unmanned to lead the way for utilities in the new era of inspections.

Contact us today and see how Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

Recently, there has been an increased adoption of digital tools to carry out overhead line inspections like the use of drones and cameras to collect imagery or visual data and manually analyze them, but a more efficient and effective method of conducting those inspections is by completely digitalizing the process and using AI technology to analyze and sort out the data. Utilities are looking at software to check the health and performance of transmission and distribution assets as part of a suite of digital tools in order to create agility and safety on that side of their operations.

In an October webinar we did with Xcel Energy, Brian Long, Xcel Energy’s Project Director for Transmission Asset Management, clarified “The main reason we do this is to improve our inventory and really understand the condition of our assets.” With fast and robust data being sent to the utility through virtual inspections, utilities can have a clearer picture of the health and efficiency of their T&D network without sending work crews which saves time, gas and labor money, and reduces worker exposure to job hazards from lines and substations. AI-based inspection solutions can also find more defects than traditional methods, and can be used with modeling tools to help predict issues with assets on a timeline which can increase both efficiency and safety.

- BVLOS flying inspected over

in a single day

The new age of powerline inspections.

When working with utilities on their infrastructure inspections, we are constantly being reminded of the immense challenges that modernization, digitalization and huge expansion poses for utilities. And we are not claiming that we can solve all of these challenges on our own, but virtual inspections can support the energy transition and is aligned with the expectations of the new revolution when it is done right.

Virtual line inspections provide a wealth of data in conjunction with various sensors and other devices that can be utilized in the decision-making process for all sorts of applications beyond just asset health. The timing of investment decisions can hinge on which systems most need addressing, and having a complete picture of one’s systems through a synthesized data repository can inform and accelerate that process. More granular data can be used to target specific parts or aspects that need addressing rather than more costly replacements of an entire unit or system. Data can also be used to create efficiencies for field crews both in management’s ability to effectively allocate their efforts, and for the crews themselves if they have easy access to the data in the field. The whole of the utility apparatus can be more deft with these data and analytics tools.

The key to unlocking the business value of virtual inspections is a smart plan executed by skilled staff

On our podcast about AI misconceptions, eSmart System’s CTO Erik Asberg said:

in the cost of drone data acquisition

It all started with five miles.

In 2015, Xcel Energy sanctioned a five-mile proof of concept transmission line inspection using drones. Limited by site access, weather, and shortened flight distances, they kept the unmanned aircraft within visual line of sight, the field crew took two and a half days to inspect five miles. Traditional foot patrol methods would have completed the inspection in a single day, underlining that something needed to change to increase the efficiency.

To get the best use out of the data and the analytics, a robust plan with buy-in from the entire organization is necessary to reach the most efficient applications of the data for the highest return of investment in terms of time, money, and safety. It is also prudent to ensure that staff is properly trained to utilize these tools, or partnerships are formed with skilled professionals familiar with these processes. Collaboration and partnership in general can help fill knowledge gaps for an organization looking to onboard more advanced systems. The tools at our disposal are capable of synthesizing a lot, but they are only tools, we cannot forget the human element.

Concluding thoughts.

Throughout this year, we’ve seen many advancements in utility infrastructure and systems as they modernize for resilience and increasing customer expectations. Making the most out of data in transmission and distribution is both part of the modernization process and an accelerant of it. By creating efficiencies in this space utilities can open up resources for further investment and planning. Collecting data can allow for proactive decision-making on upgrading which makes the grid more resilient. With a clearer understanding of assets, workers can be better allocated and hazards can be identified faster. A utility with a good plan, knowledgeable partner, and trained staff that are kept up throughout the process can use virtual inspections alongside a suite of tools to improve not just their T&D, but the whole enterprise.

Contact us today and see how Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

Join our webinar to learn how Distribution System Operator, Mitnetz Strom (part of the E.ON Group), integrates AI and drones into its grid inspection programme.

Supplying approximately 2.3 million customers with electricity, the German DSO wanted to enhance their inspections with a fully autonomous process, utilizing autonomous drones and AI-enabled image recognition. The panel of experts will share insights from the project journey including lessons learned and efficiency gains achieved to date.

In this webinar, you’ll learn about the following:

- An overview of the Mitnetz inspection programme

- Their journey in integrating AI

- Key considerations for AI implementation

- Data capture strategies

- Maximising returns from captured data

Other Webinars You May Like

-

Webinars

WebinarsWatch our webinar – Disrupting the status quo: AI in utility operations

Watch this webinar to understand why everyone is talking about AI transforming utilities’ day-to-day operations and business as a whole. Learn what leaders really need to know about these fast-moving technological changes.September 25th 2024 -

Webinars

WebinarsWatch our webinar – Master your substation asset data: Expert insights and strategies revealed

Watch this webinar to learn how to improve poor quality and incomplete data for your substations and how you can achieve lower costs and a much faster response to faulty assets by relying on accurate, up-to-date data.May 09th 2023 -

Webinars

WebinarsWatch our webinar – Incorrect asset data – why it puts congestion management strategies at risk

Stedin, DSO for 2.3+ million customers in the Netherlands, realised that the asset data they used for their network calculations resulted in anomalies. Watch this webinar to understand Stedin’s approach to validating asset data for their 22,000 Medium Voltage substations.October 02nd 2023 -

Webinars

WebinarsWatch our webinar – How AI & Virtual inspections changed operations at Xcel Energy

Inspecting transmission and distribution assets is tremendously time- and labor-intensive for utilities. Watch this webinar to learn the benefits and requirements of using a virtual inspection program and what AI is and isn’t capable of doing.May 12th 2023

Join our webinar to learn how Distribution System Operator, Mitnetz Strom (part of the E.ON Group), integrates AI and drones into its grid inspection programme.

Supplying approximately 2.3 million customers with electricity, the German DSO wanted to enhance their inspections with a fully autonomous process, utilizing autonomous drones and AI-enabled image recognition. The panel of experts will share insights from the project journey including lessons learned and efficiency gains achieved to date.

In this webinar, you’ll learn about the following:

- An overview of the Mitnetz inspection programme

- Their journey in integrating AI

- Key considerations for AI implementation

- Data capture strategies

- Maximising returns from captured data

Other Webinars You May Like

-

Webinars

WebinarsWatch our webinar – Disrupting the status quo: AI in utility operations

Watch this webinar to understand why everyone is talking about AI transforming utilities’ day-to-day operations and business as a whole. Learn what leaders really need to know about these fast-moving technological changes.September 25th 2024 -

Webinars

WebinarsWatch our webinar – Master your substation asset data: Expert insights and strategies revealed

Watch this webinar to learn how to improve poor quality and incomplete data for your substations and how you can achieve lower costs and a much faster response to faulty assets by relying on accurate, up-to-date data.May 09th 2023 -

Webinars

WebinarsWatch our webinar – Incorrect asset data – why it puts congestion management strategies at risk

Stedin, DSO for 2.3+ million customers in the Netherlands, realised that the asset data they used for their network calculations resulted in anomalies. Watch this webinar to understand Stedin’s approach to validating asset data for their 22,000 Medium Voltage substations.October 02nd 2023 -

Webinars

WebinarsWatch our webinar – How AI & Virtual inspections changed operations at Xcel Energy

Inspecting transmission and distribution assets is tremendously time- and labor-intensive for utilities. Watch this webinar to learn the benefits and requirements of using a virtual inspection program and what AI is and isn’t capable of doing.May 12th 2023

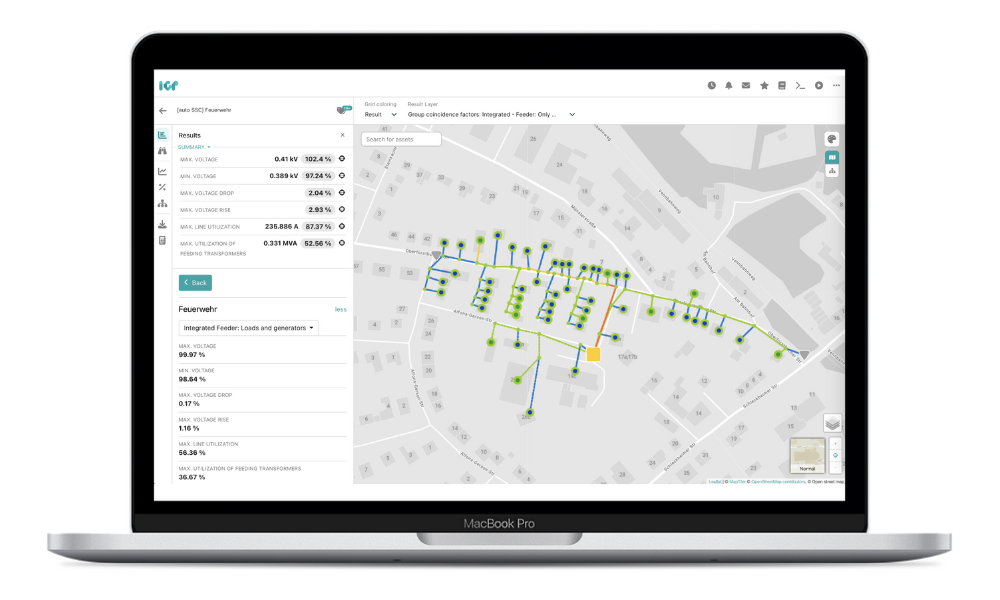

eSmart Systems and envelio are excited to announce their partnership to support utilities with their asset management and grid planning decisions.

eSmart Systems’ Grid Vision® solution powered by AI enables utilities to scale virtual inspections and grid inventory while digitalizing transmission and distribution assets with an image-based digital asset, combining inspection data, substation assets, metadata and grid topology to provide actionable insights and downstream value beyond the inspection.

envelio’s Intelligent Grid Platform empowers utilities by delivering a digital twin of the distribution grids. The platform unites relevant grid data from multiple sources into one platform to digitalize and automate grid planning and grid operation processes. Applications like Grid Planning and Grid Study enable the evaluation of future scenarios and their effect on the power grids. The results can then be used for strategic grid planning.

Bringing the two solutions together unlocks a powerful combination of an accurate image-based digital asset with the digital twin, resulting in a knowledge-based platform to support utilities to break down silos between grid operations, investment planning and condition monitoring to provide holistic and accurate information on the conditional and physical state of the grid. Based on these additional insights on the power flow and mechanical asset data combined, utilities can enable improved maintenance and inspection planning, support unplanned outage response and improve long term asset investments and strategic grid planning for their power grids.

The partnership between eSmart Systems and envelio will enable a giant leap in the cross-functional use of data from both our worlds. This will benefit multiple departments and user groups within the utility, due to the exchange and uplift of the different types of information we each focus on.

Innovation partnerships like the one with eSmart Systems are the key to the energy transition. Together we create a solution with a technological best-of-breed approach that enables cost-optimized and accelerated asset management and expansion planning of the power grids and thereby supporting grid operators in meeting the challenges of the energy transition.

In this whitepaper, learn what to consider and how you can realize the benefits of the new generation of infrastructure inspections and increase the resiliency of your power grid.

Join our webinar to learn how Distribution System Operator, Mitnetz Strom (part of the E.ON Group), integrates AI and drones into its grid inspection programme.

Supplying approximately 2.3 million customers with electricity, the German DSO wanted to enhance their inspections with a fully autonomous process, utilizing autonomous drones and AI-enabled image recognition. The panel of experts will share insights from the project journey including lessons learned and efficiency gains achieved to date.

In this webinar, you’ll learn about the following:

- An overview of the Mitnetz inspection programme

- Their journey in integrating AI

- Key considerations for AI implementation

- Data capture strategies

- Maximising returns from captured data

Other Webinars You May Like

-

Webinars

WebinarsWatch our webinar – Disrupting the status quo: AI in utility operations

Watch this webinar to understand why everyone is talking about AI transforming utilities’ day-to-day operations and business as a whole. Learn what leaders really need to know about these fast-moving technological changes.September 25th 2024 -

Webinars

WebinarsWatch our webinar – Master your substation asset data: Expert insights and strategies revealed

Watch this webinar to learn how to improve poor quality and incomplete data for your substations and how you can achieve lower costs and a much faster response to faulty assets by relying on accurate, up-to-date data.May 09th 2023 -

Webinars

WebinarsWatch our webinar – Incorrect asset data – why it puts congestion management strategies at risk

Stedin, DSO for 2.3+ million customers in the Netherlands, realised that the asset data they used for their network calculations resulted in anomalies. Watch this webinar to understand Stedin’s approach to validating asset data for their 22,000 Medium Voltage substations.October 02nd 2023 -

Webinars

WebinarsWatch our webinar – How AI & Virtual inspections changed operations at Xcel Energy

Inspecting transmission and distribution assets is tremendously time- and labor-intensive for utilities. Watch this webinar to learn the benefits and requirements of using a virtual inspection program and what AI is and isn’t capable of doing.May 12th 2023

The project, completed in 2021, focused on hardware and defects identification. The project looked at cotter pins, with an emphasis on loose and upside-down cotter pins. The project was able to automatically detect over 11,000 total and successfully identify 781 upside-down pins within a few seconds. The project enabled the public utility’s maintenance engineers to efficiently locate the 2-inch upside-down cotter pins on up to 100 feet high towers and assess their conditions. The outcome of the project is an increase in powerline safety, field worker safety, and, as result, community safety. The case-study described below demonstrates the potential of virtual powerline inspections in enhancing community safety.

Introduction

Multiple large-scale wildfires are reported in the US every year. Such events cost tens of billions of dollars in direct costs such as property loss and damage and indirect costs such as long-term health exposures, market loss, and non-collectable taxes, etc[1]. The consequences of such events can be disastrous from a human, material, and environmental perspective.

Defects in the power grid can cause wildfires; active causes can include a tree or branch falling over a powerline and sparking a wildfire. Triggered material or old powerline components can generate arcs or sparks, and under dry weather conditions and with dry surrounding vegetation, can lead to disastrous and hard to control wildfires.

- BVLOS flying inspected over

in a single day

The new age of powerline inspections.

When working with utilities on their infrastructure inspections, we are constantly being reminded of the immense challenges that modernization, digitalization and huge expansion poses for utilities. And we are not claiming that we can solve all of these challenges on our own, but virtual inspections can support the energy transition and is aligned with the expectations of the new revolution when it is done right.

Cotter pins, however, could wear out and loosen over time. A loose and upside-down cotter pin is more likely to slip, becoming unsafe and increasing the chance of conductor failure and the probability of generating an arc flash touching their surroundings. Therefore, a main focus of the efforts led by the public utility to minimize the chance of wildfires is the management and maintenance of cotter pins specifically. As they are more likely to be upside-down than loose, the public utility decided to first assess the number of upside-down cotter pins on their grid. However, manually identifying the orientation of cotter pins is a tedious and resource-consuming task, as there can be as many as 50 2-inch cotter pins on each lattice tower, and the grid in this case includes over 1000 lattice towers.

The new approach

Both the public utility and the engineering and construction company defined the inspection process based on the required scope and accessibility of each structure. eSmart Systems shared their expertise to support that process definition and provided access to Grid Vision, a virtual inspection solution for power grids, enabling professionals to inspect powerlines from the office. Virtual inspection is a new approach to conducting powerline inspections by leveraging the power of automation, smart algorithms, and user-friendly interfaces to facilitate the work of the professionals analyzing the status of the infrastructure. Virtual inspections are also supported with artificial intelligence (AI) to automatically and promptly identify all the components of a power grid, as well as to detect various failures in the grid. With the application of such technologies, the software was able to identify 781 instances of upside-down cotter pins out of 11,000 cotter pin crops, within seconds (Figure 1).

Figure 1: Examples of an upside-down cotter pin automatically detected in the grid.

By associating those findings with information of the tower on which the upside-down cotter pins were located, the public utility could identify which towers required attention instantly. This approach has improved the efficiency and accuracy of identifying upside-down cotter pins and improved safety by having line workers only climbing structures when needed.

The utility also looked at other types of key components and their failure modes (flashed insulators, woodpecker damage on wooden transmission towers, rust on lattice towers, etc.) that could be identified utilizing this new approach for a proactive maintenance of powerlines. C-hooks and shackles, which are used for affixing insulators to brackets attached to crossarms, are particularly important components to look at in this context. The lattice towers are over 50 years old. Nonetheless, the virtual detection system was able to identify over 25,000 crops of C-hooks and shackles on the images captured during the inspection and very little wear was detected.

Figure 2: Examples of (a) a c-hook in good condition, (b) very limited level of wear seen on c-hooks during the project and (c) a shackle, highlighting the general good condition of those components in the grid.

Utilities are constantly looking for innovative ways to improve safety inspection and grid maintenance. This project has demonstrated that well-designed solutions supported by AI are game-changing tools, making inspection easier, more efficient and safer. The collaborative AI approach was instrumental to ensuring the correct components were identified and defects detected. The construction company’s review of the results from eSmart Systems’ Grid Vision solution ensured that high quality inspection standards were met and illustrated how utilities and engineering companies can benefit from virtual inspection tools.

The success of this program demonstrates how proactive actions can be implemented to enhance power grid management efficiency, and proves that smart solutions could help prevent wildfires, in addition to illustrating numerous other advantages, such as new quality assessment possibilities, defect detection standardization, and increased trust in data.

Contact us today and see how Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

[1]https://www.nfpa.org/News-and-Research/Publications-and-media/NFPA-Journal/2020/November-December-2020/Features/Wildfire